Products

产品概述 PRODUCT BRIEF

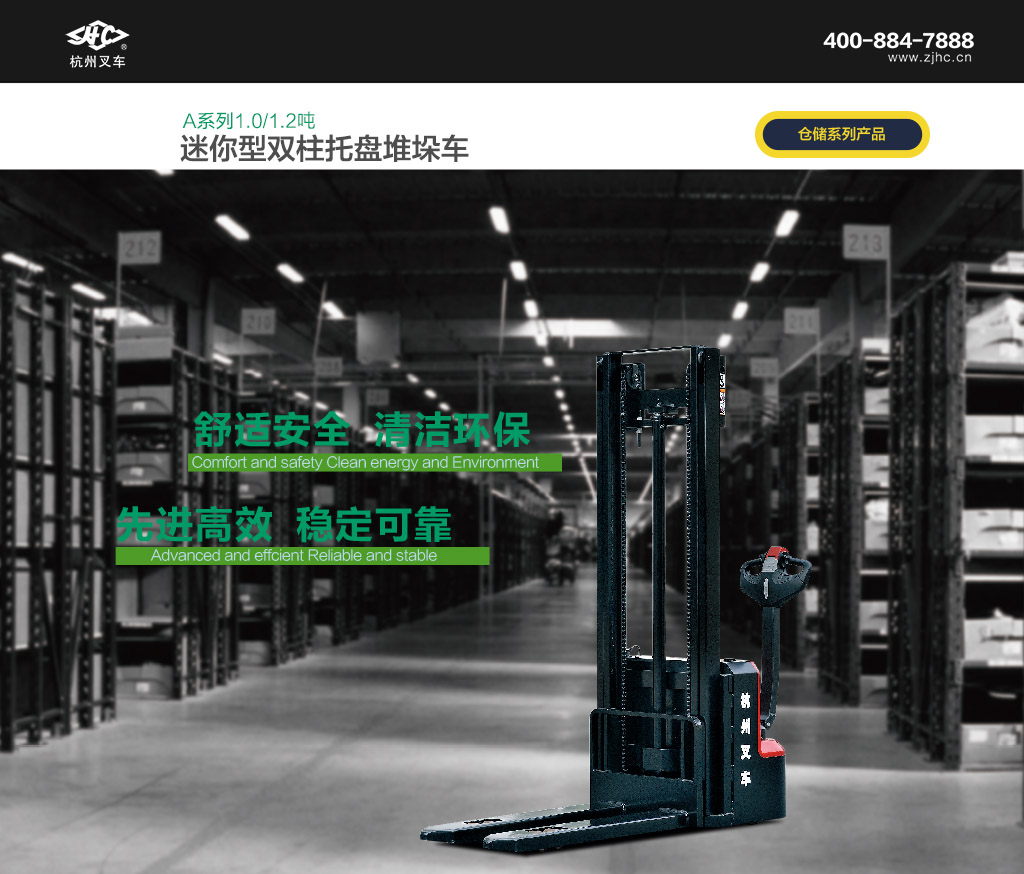

● A series Mini double column pallet stacker is a new generation of products newly developed by Hangzhou forklift for warehousing and logistics applications. It adopts new permanent magnet drive technology, with advanced performance, comfortable operation, safety and reliability, and low maintenance cost. It is an ideal tool for loading, unloading and carrying palletized goods in warehouses, supermarkets, workshops and families.

产品简介 PRODUCT INTRODUCTION

产品简介 PRODUCT INTRODUCTION

01 / appearance

The a series Mini double column pallet stacker adopts professional appearance industrial design, with smooth lines, dynamic, compact shape, fully considering ergonomics, in line with the new appearance design trend.

A large number of steel plate stamping and injection molding processes are adopted, which are durable, high-grade and meet the requirements of environmental protection.

02 / high performance

With powerful power and 1 ton load, it can meet the handling requirements of most customers.

The permanent magnet walking motor has excellent performance and low calorific value.

The new Curtis permanent magnet control system has excellent control performance, high efficiency and stability.

The vehicle has regenerative braking and slope anti sliding protection

The control handle, hydraulic pump station, switch, plug-in parts, electric quantity display meter, timing meter and other important parts are foreign famous brand products.

03 / comfort

Imported rema control handle, beautiful and simple, all operation functions can be easily completed by one hand.

The optimized design of the body structure ensures that the forklift has a wide operating field of vision and is more convenient to get in and out of the pallet.

Built in charger, gel maintenance free battery, easy to use.

It is small in size, light and flexible, and easy to operate. It can also pass through very small channels.

It has the function of upright walking, which can operate the vehicle in a smaller space

04 / reliability

The frame is of high strength steel plate frame structure, with large residual bearing capacity and long service life.

The four fulcrum design is adopted, the load distribution of driving wheel is reasonable, the wheel has good grip, and at the same time, it ensures good stability and vision.

The whole system adopts imported waterproof connector, all wires and cables have reliable protection, which greatly improves the reliability of the electrical system

International first-class lifting, low vibration and low power.

The flexible connection between hydraulic unit and frame can absorb the vibration transmitted from uneven road surface to hydraulic unit, and increase the reliability of hydraulic unit.

The stamping fork has higher strength and impact resistance, and further improves the operation efficiency with fork tip guidance.

05 / safety

It has release brake, reverse brake and three kinds of emergency braking functions to ensure the safety of driving.

At the same time, it has the function of slope anti sliding to ensure the operation safety.

The emergency reverse button on the head of the handle can effectively prevent the driver from being injured in case of emergency when driving backward.

When the fork is less than a certain height from the ground, it will automatically slow down the descent speed and effectively protect the cargo safety.

06 / maintenance

It is equipped with built-in charger and maintenance free battery as standard, without maintenance.

The display of electric quantity will prompt the user to charge in time.

The rear hood can be completely opened, and the components are clear at a glance, so that the maintenance of the whole machine is very convenient.

All rotating shafts are equipped with lubricating shaft sleeve and oil cup, which is convenient for maintenance and long service life.

The frame and portal frame are assembled, and the maintenance is convenient.

It is not convenient to lift the auxiliary wheel from the upper part of the vehicle.

Product configuration PRODUCT CONFIGURATION

Standard configuration

Permanent magnet drive motor

Curtis permanent magnet controller

Hydraulic power unit

Emergency power off switch

Electricity meter

Polyurethane wheel

Fork length 1150 mm

Outer spacing of fork 560mm

Multi function handle

horn

Maintenance free battery

Built in charger

Optional configuration

2-3.3m gantry

1220 / 1400mm fork length

Outer spacing of 680mm fork

For cold storage (low temperature protection to - 30 ℃)

Block the shelf

Product parameters PRODUCT PARAMETER

| manufacturer | Hangzhou fork group |

|---|

| model |

| 1.0 tons | 1.2 tons | 1.0 ton straddle type | 1.2 ton straddle type |

| Rated lifting capacity | kg | one thousand | one thousand and two hundred | one thousand | one thousand and two hundred |

| Load center distance | mm | six hundred | six hundred | six hundred | six hundred |

Maximum lifting height | mm | three thousand | three thousand | three thousand | three thousand |

Minimum turning radius | mm | one thousand four hundred and sixty-six | one thousand four hundred and sixty-six | one thousand four hundred and sixty-six | one thousand four hundred and sixty-six |

Maximum driving speed (full load / no load) | km/h | 4/4.5 | 4/4.5 | 4/4.5 | 4/4.5 |

Maximum lifting speed (full load / no load) | mm/h | 120/190 | 120/190 | 120/190 | 120/190 |

Maximum climbing gradient (full load / no load) | % | 6/10 | 5/10 | 5/10 | 5/10 |

| Total length (pedal retracted) | mm | one thousand and eight hundred | one thousand and eight hundred | one thousand eight hundred and thirty-six | one thousand eight hundred and thirty-six |

| Full width | mm | eight hundred | eight hundred | 1100/1270/1470 | 1100/1270/1470 |

Total weight (including battery) | kg | seven hundred and forty-four | seven hundred and sixty | seven hundred and forty-four | seven hundred and sixty |

Power of traveling motor [S2 60 min working system] | kW | zero point seven | zero point seven | zero point seven | zero point seven |

Lifting motor power [15 min working system] | kW | two point two | two point two | two point two | two point two |

| controller |

| Curtis communication | Curtis communication | Curtis communication | Curtis communication |

Products and specifications, if there are changes due to improvement, will not be notified, subject to the actual object.

after-sale service Customer Service

● Please contact the subsidiary company and authorized distribution service provider of Hangzhou fork Group Co., Ltd.

产品简介 PRODUCT INTRODUCTION

产品简介 PRODUCT INTRODUCTION